THE CRAWLER Cranes :

THE CRAWLER Cranes :

- HITASHI KH110 (35 TON).

- P&H KH150 (40 TON).

- HITASHI KH180 (50 TON).

- AMERICAN 7260 (100TON).

- MANTOC (150 TON).

- P&H (300 TON).

Concrete pump:

Placing boom 61 R

Compact 4-section placing boom in roll and fold design, made of fine grain steel with

attached pipeline, resting on a slewable base column with fully hydraulic and telescopic

outriggers. Operation of the boom by proportional remote control. Manual boom control for emergency recovery.

With the following configuration:

Number of articulations 4

Vertical reach 61,00 mt

Horizont. reach f. cen. Turret 56,40 mt

Slewing range 2 x 185°

Pumpkit

Fitted with the SCHWING Rock Valve with automatic adjustment of the cutting ring by means of a prestressed rubber spring. Easy access for cleaning and maintenance resulting in low wearing costs.

Ready-to-operate concrete pump. Fully hydraulic concrete pump control system in the

reliable open hydraulic circuit. Easy to operate and to maintain. Prime coat and finishing

coat.

Technical Data

Type P 2525-120/85

Hydr. drive max. V 636 l / min.

Theor. concrete output 162 m³/h

Dia. of pumping cylinders 250 mm

Piston stroke 2.500 mm

Max. number of strokes 22 / min.

Capacity of agitator hopper approx 500 l

Charging height approx 1.350 mm

Drive system Twin circuit hydraulic

MPS-Accumulator incl.

Valve system B-Rock

Pump cylinder DN 250 chrome

Hopper cover with incl. Locking

Pipeline

Boom pipeline Super 3000 DN 112

Pipeline outlet Super 3000 DN 125

Outlet variants standard

End hose 3 m DN 112

Base Frame

Outrigger System Full – support

Outrigger pads 12 PCS Multiplex-Pads

Operating System

Control system VECTOR

The microcontroller-based control system VECTOR used to convert the machine function in the mode local, remote and ramp change. The system offers next to an integrated diagnostic system a wide range of assistance to help and relieve the machine operator in the operation and maintenance of the concrete pump.

Language Control System english

Remote control SCHWING Control 30

Proportional remote control Schwing Control 30 with 2 joysticks and display for metering

general machine parameter. The SCHWING Control 30 can be used in wireless and cable linked mode.

Scope of supply: 1 x transmitter with carrying strap, 1 x receiver, 2 x rechargeable batteries, 1 x battery recharger, 1 x 20m cable for teach- and cable linked mode.

add cable for remote control 1 connecting cable M12, 20m

Horn tracer hopper area on the right

Concrete output adjustment 0 – max. standard

Emergency supply boom Hand pump

Lighting

Rear lights included

Spot hopper area at the hopper left LED

Delivery System

Water tank 610 l rear center

Water system Roller water pump

Water tank filling C-connection series

Hydraulic oil filling Hydraulic oil HLVP 46

Oil cooler version hydr. driven cooler

Monitoring hydraulicoil niveau included

Greasing system central greaser strip Rock

Supply control with

The supply control and integrated local control at the rear of a SCHWING truck-mounted

concrete pump enables the machinist to control all functions and operations for the work

preparation, cleaning and maintenance, without climbing onto the machine. Furthermore, the hydraulic pressure of the concrete pump and MPS can be read.

Features supply control:

Water box filling/flushing, c-connection for the filling and emptying of the water tank, output of water pump (spray hose) 12 / 20 bar, lubrication point of rock and agitator, display of the hydraulic pressure of the concrete pump and the MPS (mini pause switch).

Features local control:

Motor start/stop, motor speed adjustment, concrete pump output regulation, agitator switch pump operation/suction operation, concrete pump switch pump operation/suction operation, water pump control.

Mounting Parts

access right hinged step

Truck

Chassis manufacturer Mercedes-Benz

Series MB-AC (MP3)

Truck model 5050 K

Chassis cab middle long

Axle configuration 10×4/6

Engine performance KW/PS 370/503

Exhaust standard EURO 3

Drive unit Direct drive via chassis PTO

Drive shafts standard

Painting

Scope of paint Paint one color

Color code MB 9147 arctic white

Change color of chass. cab remains as delivered

chassis cab colour code MB 9147 arctic white

Labelling SCHWING Standard

THE TRUCK Cranes

THE TRUCK Cranes :

- DEMAG HC75 (28TON ).

- Koto ( 20TON ).

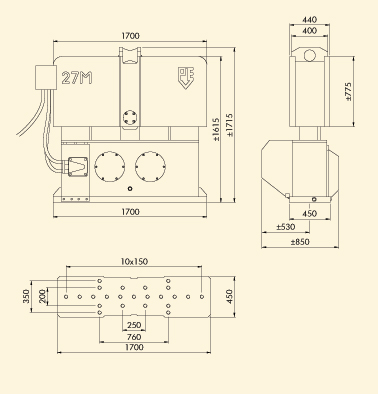

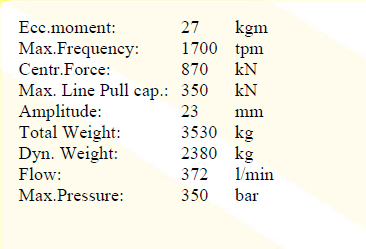

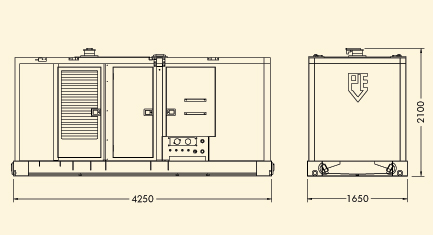

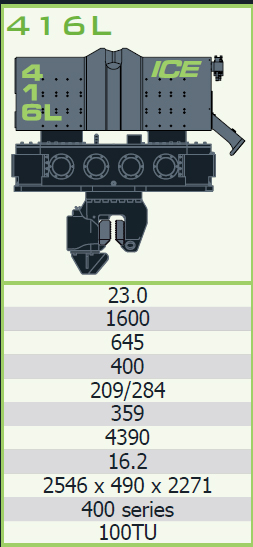

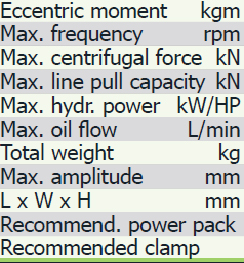

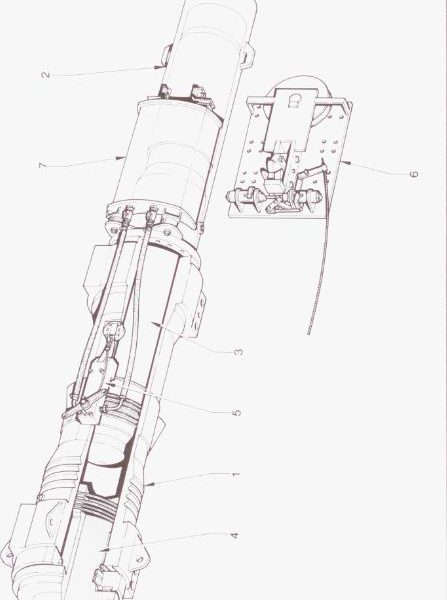

Vibratos Hummer

Vibratos Hummer:

- PILING AND VIPRO P. V. E 27 M.

- PILING AND VIPRO P. V. E 38 M.

- VIBRATORY HUMMER ICE 416 L

- PILING AND VIPRO P. V. E 52 M Delmag D 18 . Delmag D 22 .

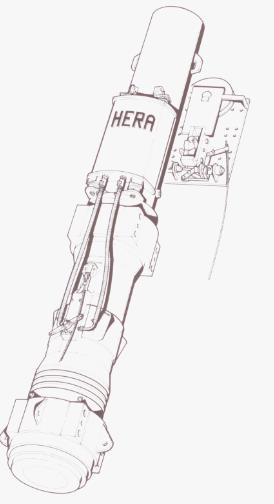

- Hera 8800 . IHC S150

Wheel Loader

Wheel Loader :

- FURUKWA 365.

- CAT 936 F.

HYDROLIC EXCAVATOR

HYDROLIC EXCAVATOR :

- KOMATSU PC 210 ( 2 UNITS ).

DUMP TRUCKS (FOR SAND AND ROCKS)

DUMP TRUCKS (FOR SAND AND ROCKS)

- MAN

- MERCEDES

- IVECO

- RENAULT

Diesel Generators

Diesel Generators :

- Generator sets different power

Diesel hummer

Diesel hummer:

- Mitsubishi M . H 45 .

- Mitsubishi M . H 25 .

- Kobe K . 25 .

- Delmag D 18 .

- Delmag D 22 .

- Hera 8800 .

- IHC S150

All Air Compressor, Welders of different sizes,

HITASHI Hyrdrolic Jack Hummer and Grabs used for sand & rock

HITASHI Hyrdrolic Jack Hummer and Grabs used for sand & rock